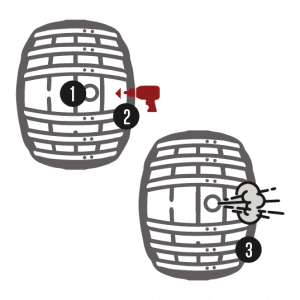

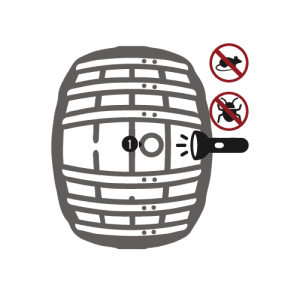

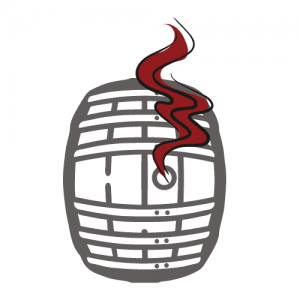

5 Step Barrel Inspection

Let's Have a Look at the Barrel Inspection Process

Here is a look at how we to perform barrel inspections. These inspections are crucial for ensuring that the barrel has no damage or imperfections that could lead to leaks, bacteria, or off flavors during the barrel aging process.